601 Inconel Rings

Price 754 INR/ Kilograms

601 Inconel Rings Specification

- Hardness

- 160-220 HB (Brinell)

- Material Composition %

- Nickel 58-63%, Chromium 21-25%, Aluminium 1-1.7%, balance Iron, other elements as trace

- Diameter

- Typically 20 mm to 1500 mm (customizable)

- Heat Resistance

- Yes

- Size

- Standard and custom sizes possible

- Corrosion Resistant

- Excellent, especially against oxidation and carburization

- Recyclable

- Yes

- Product Form

- Ring

- Coating Type

- None (raw alloy finish), special coatings available on request

- Tensile Strength

- Min. 550 MPa

- Product Name

- 601 Inconel Rings

- Steel Type

- Nickel-Chromium Alloy (Superalloy)

- Steel Product Type

- Forged Ring

- Grade

- Inconel 601

- Thickness

- As required by specification (typically 1 mm to 50 mm)

- Shape

- Ring

- Steel Standard

- ASTM B166 / ASME SB166

- Surface

- Bright / Polished / Machined

- Composition

- Nickel, Chromium, Aluminium, Iron, trace elements such as Silicon, Manganese, Copper, Carbon, Sulfur

- Application

- High temperature industrial applications, furnace components, petrochemical & chemical processing, heat-treating baskets and fixtures, gas turbine components

- Dimension (L*W*H)

- Custom as per requirement

- Weight

- Varies depending on size and thickness

- Color

- Metallic Silver

- Material Grade

- Alloy 601

- Finish Type

- Machined / Polished

- Usage

- Used in heat treating industries, power generation, and chemical processing

- Density

- Approximately 8.11 g/cm³

- Standards Compliance

- ASTM, EN, DIN, JIS available upon request

- Elongation at Break

- 30% min

- Magnetic Properties

- Non-magnetic

- Thermal Conductivity

- 15.0 W/m·K at 100°C

- Manufacturing Process

- Hot forged and heat treated

- Lead Time

- 2-4 weeks, depending on size and quantity

- Melting Point

- 1370-1410°C

- Service Temperature

- -200°C to +1200°C

- Packaging

- Export standard wooden boxes or as per request

601 Inconel Rings Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About 601 Inconel Rings

Superior Material for Extreme Conditions

Forged from Inconel 601, these rings offer remarkable resistance to high temperatures and corrosive environments. With a melting point range of 1370-1410C and thermal conductivity of 15.0 W/mK at 100C, they remain stable in industrial furnaces and reactors. Their robust structure, coupled with non-magnetic properties, makes them reliable for applications in heat treatment, petrochemical, and gas turbine industries.

Custom Solutions and International Compliance

601 Inconel Rings can be tailored to precise dimensions and thicknesses ranging from 1 mm to 50 mm. They adhere to globally recognized standards like ASTM B166 / ASME SB166, ensuring consistent quality. Whether you need a bright, polished, or machined finish, these rings are packaged securely in export-standard wooden boxes and shipped worldwide, with lead times of 24 weeks depending on order size.

FAQs of 601 Inconel Rings:

Q: How are 601 Inconel Rings manufactured?

A: 601 Inconel Rings are produced through a hot forging process followed by heat treatment, enhancing their strength and resistance to oxidation. The rings can be machined, bright polished, or left with a raw alloy finish according to customer specifications.Q: What are the typical applications of Inconel 601 rings?

A: These rings are widely used in high-temperature industrial settings such as furnace components, heat-treating baskets, petrochemical and chemical processing equipment, and gas turbine components due to their exceptional heat and corrosion resistance.Q: When should Inconel 601 rings be chosen over other materials?

A: Inconel 601 rings should be selected when operations involve exposure to extreme temperatures (up to 1200C), aggressive atmospheres, or require outstanding oxidation resistance, where standard stainless steels might fail.Q: Where are 601 Inconel rings commonly exported from and supplied to?

A: These rings are manufactured in India and exported globally. They are supplied to industries such as power generation, aerospace, heat treating, and chemical processing in countries across North America, Europe, Asia, and the Middle East.Q: What benefits do 601 Inconel rings offer in harsh environments?

A: 601 Inconel Rings provide long-term stability, low maintenance, and resistance to scaling and carburization. Their robust composition ensures minimal performance degradation even after prolonged exposure to corrosive or oxidizing environments.Q: How is the packaging of Inconel 601 rings managed for export?

A: The rings are packed in export-standard wooden boxes or as per customer requirements. This ensures safe and damage-free delivery, regardless of transit duration or distance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel 601 Products Category

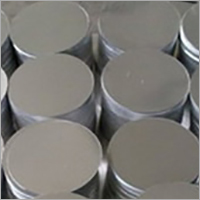

601 Inconel Sheets

Price 945 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Thickness : 0.5 mm to 100 mm (Available Range)

Steel Standard : Other, ASTM B168 / ASME SB168

Grade : 601

Corrosion Resistant : Excellent resistance to oxidation and corrosive atmospheres

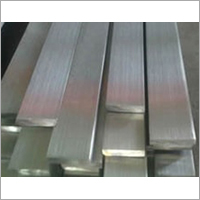

601 Inconel Flat Bars

Price 910 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Thickness : 2 mm to 50 mm

Steel Standard : Other, ASTM B166 / ASTM B168

Grade : Inconel 601

Corrosion Resistant : Excellent resistance to oxidation and corrosion at high temperatures.

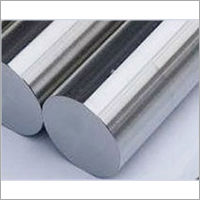

601 Inconel Round Bars

Price 915 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Thickness : Ranges from 2mm to 250mm

Steel Standard : Other, ASTM B166, ASME SB166

Grade : Inconel 601

Corrosion Resistant : Excellent

601 Inconel Fasteners

Price 5 INR / Piece

Minimum Order Quantity : 100 Kilograms

Thickness : 5 Millimeter (mm)

Steel Standard : AISI

Grade : 201

GST : 27AATFN5206C1ZA

|

|

NANDISHWAR STEEL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry