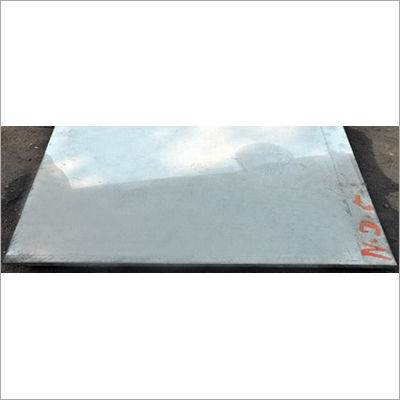

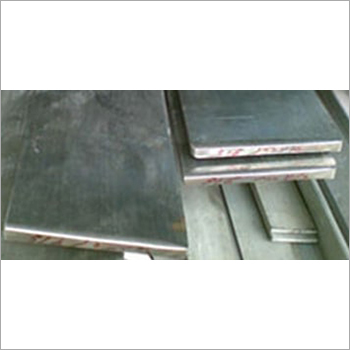

Duplex UNS S31803 Flat Bar

Price 307 INR/ Kilograms

Duplex UNS S31803 Flat Bar Specification

- Coating Type

- Uncoated / As per customer demand

- Product Form

- Hot Rolled / Cold Drawn Flat Bar

- Hardness

- 293 HB maximum

- Diameter

- Not Applicable (Flat Bar)

- Size

- Available in various sizes from 20mm to 300mm width and custom length

- Material Composition %

- Cr (2123%), Ni (4.56.5%), Mo (2.53.5%), N (0.080.20%), Fe (Balance)

- Corrosion Resistant

- Excellent corrosion resistance to stress corrosion, crevice and pitting corrosion

- Heat Resistance

- Yes

- Tensile Strength

- 620 MPa (minimum)

- Recyclable

- Yes, 100% recyclable

- Product Name

- Duplex UNS S31803 Flat Bar

- Steel Type

- Duplex Stainless Steel

- Steel Product Type

- Flat Bar

- Grade

- UNS S31803

- Thickness

- 3 mm to 100 mm

- Shape

- Flat

- Steel Standard

- ASTM A276, ASTM A240, EN 10088

- Surface

- Pickled, Bright, Polished or as required

- Composition

- Duplex Stainless Steel - Chromium, Nickel, Molybdenum, Nitrogen

- Application

- Construction, Chemical Processing, Marine Engineering, Oil & Gas, Paper & Pulp Industry, Food Processing

- Dimension (L*W*H)

- Customizable as per order requirements

- Weight

- Variable (Depends on dimension and length)

- Color

- Metallic Silver

- Material Grade

- S31803

- Finish Type

- Mill, Bright, Polished

- Usage

- Structural Support, Brackets, Engineering Components, Fabrication

- Density

- ~7.8 g/cm³

- Packing

- Standard export seaworthy packing or as required

- Weldability

- Excellent, suitable for all standard welding processes

- Marking

- Product identification by heat number and grade

- Machinability

- Good machinability with appropriate tooling

- Length Tolerance

- +/- 2mm or as specified

- Magnetic Properties

- Slightly magnetic due to duplex structure

- Edge Condition

- Square Edge or Custom Profiled

- Delivery Condition

- Annealed / Solution Treated

Duplex UNS S31803 Flat Bar Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Duplex UNS S31803 Flat Bar

Versatile Usage and Distinguished Material Features

Duplex UNS S31803 Flat Bars are designed for structural support and demanding fabrication in construction, chemical processing, marine engineering, oil & gas, paper & pulp, and food processing industries. Their potent duplex stainless steel composition ensures illustrious corrosion, stress, and heat resistance. Perfect for brackets, frameworks, or custom engineering components, these bars adaptability makes them a sizzling asset in both heavy-duty projects and fine fabrication alike. Choose from a wealth of sizes and surface finishes tailored to your usage type.

Packaging, Delivery, and Sample Provisions

Our Duplex UNS S31803 Flat Bars are securely packed in standard export-approved, seaworthy packaging to guarantee safe drop-off and pristine arrival. With each handover, product identification by heat number and grade brings assurance of authenticity. FOB Ex-Works, Mumbai, India, is the regular port, ensuring reliable export logistics. For quality assurance, samples can be provided before the contract handover, letting you assess our crackerjack product first-hand before major deployment.

FAQs of Duplex UNS S31803 Flat Bar:

Q: How does the Duplex UNS S31803 Flat Bar benefit industrial applications?

A: With its excellent corrosion resistance, high strength, and good machinability, the Duplex UNS S31803 Flat Bar is ideal for structural support and complex fabrication in industries such as construction, marine, and chemical processing.Q: What is the customizability range for dimensions and surface finishes?

A: Lengths, width (20mm to 300mm), thickness (3 mm to 100 mm), and surface finish (pickled, polished, or bright) can all be customized according to your specified requirements or project needs.Q: Where does packaging and drop-off typically take place for export orders?

A: Most export shipments are drop-shipped FOB Ex-Works, Mumbai, India. Each order is packed in seaworthy packaging to ensure safe transport and condition upon arrival at your location.Q: What identification and marking process is followed for the flat bars?

A: Every Duplex UNS S31803 Flat Bar is marked with its heat number and grade, providing complete traceability and assurance of the materials origin, ensuring transparency and quality control.Q: When can I request a sample of this flat bar?

A: You can request a sample before finalizing your bulk order; samples are provided to allow you to evaluate the products quality and suitability for your application.Q: What makes the Duplex structure slightly magnetic, and does it impact usage?

A: The duplex microstructure (combining austenitic and ferritic phases) imparts slight magnetism. This property does not affect the overall performance or suitability for standard industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in UNS S31803 Duplex Steel Products Category

Duplex UNS S31803 Circles

Price 265 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Shape : Other, Circle

Application : Other, Oil & Gas, Chemical Processing, Marine, Power Generation, Paper & Pulp, Heat Exchangers

Steel Product Type : Other, Circle

Product Name : Other, Duplex UNS S31803 Circles

Duplex UNS S31803 Fasteners

Price 1 INR / Piece

Minimum Order Quantity : 100 Kilograms

Shape : Other, Hex, Round, Square, Threaded, Customized

Application : Other, Oil & Gas, Chemical Processing, Marine, Petrochemical, Power Plant, Desalination, Food Processing

Steel Product Type : Other, Fasteners (Bolts, Nuts, Screws, Washers, Studs)

Product Name : Other, Duplex UNS S31803 Fasteners

Duplex UNS S31803 Round Bars

Price 256 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Shape : Other, Round

Application : Other, Construction, Petrochemical, Oil & Gas, Marine, Power Plant, Chemical Processing

Steel Product Type : Other, Round Bar

Product Name : Other, Duplex UNS S31803 Round Bars

Duplex Stainless Steel Sheets

Price 307 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Shape : Other, Rectangular

Application : Other, Chemical Processing, Oil & Gas, Marine, Power Generation, Pulp & Paper, Heat Exchangers, Pressure Vessels

Steel Product Type : Other, Sheet

Product Name : Other, Duplex Stainless Steel Sheets

GST : 27AATFN5206C1ZA

|

|

NANDISHWAR STEEL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry