Inconel Alloy Fasteners

Price 5 INR/ Piece

MOQ : 100 Kilograms

Inconel Alloy Fasteners Specification

- Coating Type

- Uncoated/Plain, can be passivated

- Hardness

- Up to 45 HRC (Rockwell)

- Heat Resistance

- Yes

- Diameter

- M4 to M36

- Material Composition %

- Nickel: 58-72%, Chromium: 14-23%, Iron: 6-12%, Others: trace

- Product Form

- Bolt, Nut, Washer, Screw

- Tensile Strength

- Up to 965 MPa (depending on grade)

- Size

- M4-M36

- Recyclable

- Yes

- Corrosion Resistant

- Excellent, resistant to acids, salts, oxidation

- Product Name

- Inconel Alloy Fasteners

- Steel Type

- Nickel-Chromium Alloy Steel

- Steel Product Type

- Fasteners (Bolts, Nuts, Screws, Washers)

- Grade

- Inconel 600/601/625/718

- Thickness

- As per standard; usually 2 mm to 20 mm

- Shape

- Round Head, Hex Head, Oval

- Steel Standard

- ASTM B166/B564/B637

- Surface

- Smooth, Polished

- Composition

- Nickel, Chromium, Iron; may contain Molybdenum, Niobium depending on grade

- Application

- Industrial, Aerospace, Petrochemical, Marine, Power Generation

- Dimension (L*W*H)

- M4 to M36 (Diameter); Length: Up to 200 mm

- Weight

- Varies based on size; typically 10 g to 500 g per piece

- Color

- Metallic Silver/Grey

- Material Grade

- 600/601/625/718

- Finish Type

- Polished / Brushed

- Usage

- Securing components in harsh environments

- Sulphur Content

- Max 0.015%

- Thread Type

- Metric, UNC, UNF as specified

- Fatigue Resistance

- High

- Temperature Range

- -60C to +1250C

- Oxidation Resistance

- Superior at high temperatures

- Magnetic Properties

- Non-magnetic

- Elongation

- Up to 40% (depends on grade)

- Packaging Type

- Box/Carton/Wooden Case

- Electrical Resistivity

- 1.03 m

- Custom Sizes Available

- Yes

- Thermal Expansion

- 1.3 x 10/K

- Head Style

- Hex, Cap, Button, Socket

- Flexural Strength

- High, suitable for dynamic loads

- Density

- 8.4 g/cm

- Lead Time

- 7-30 days based on quantity

- Melting Point

- 1270C to 1350C

Inconel Alloy Fasteners Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About Inconel Alloy Fasteners

We are offering a wide array of Inconel Alloy Fasteners. These are cherished in the market for its high mechanical strength and readily welded. These are made with a solid construction of nickel-chromium-molybdenum alloys to utilized in elevated temperatures. Inconel Alloy Fasteners are used in the aerospace industry. These are easy to removed and dismantled in a reliable manner. These fasteners create a non-permanent joints. They are delivered within a stipulated time period.

Superior Performance in Extreme Conditions

Inconel Alloy Fasteners are designed to maintain integrity and strength in temperature extremes, outperforming conventional fasteners in demanding industrial sectors. Their resilience to high heat and corrosive agents ensures secure assembly for critical systems, making them a trusted choice in aerospace and petrochemical environments. The non-magnetic alloy composition further enhances their suitability for specialized applications.

Precision Customization

Choose from a spectrum of thread typesMetric, UNC, and UNFand head styles such as hex, cap, button, and socket. Custom dimensions, finishes, and grades are available to suit the needs of various industries. Every batch undergoes rigorous quality checks, meeting standards like ASTM B166/B564/B637 to guarantee durability and reliability.

Long-Term Reliability and Versatile Usage

With high fatigue and flexural strength, these fasteners secure components subjected to dynamic loads, while their polished, corrosion-resistant surfaces withstand exposure to corrosive substances and environments. Their recycling potential and customizable manufacturing processes support sustainable engineering objectives.

FAQs of Inconel Alloy Fasteners:

Q: How do Inconel Alloy Fasteners benefit applications in harsh temperature environments?

A: Inconel Alloy Fasteners offer exceptional stability and strength from -60C up to +1250C, making them ideal for high-temperature and cryogenic environments in industries like aerospace, petrochemical, and power generation.Q: What types of fastener forms and head styles are available for custom orders?

A: Fasteners are available as bolts, nuts, washers, and screws with head styles including hex, cap, button, and socket. Sizes can be customized from M4 to M36 diameter, up to 200 mm length, allowing tailored solutions for different projects.Q: When is it recommended to use Inconel Alloy Fasteners instead of standard steel fasteners?

A: Use Inconel Alloy Fasteners when applications require resistance to oxidation, high fatigue strength, non-magnetic properties, and superior corrosion protection in extreme environments or where high operating temperatures are present.Q: Where are Inconel Alloy Fasteners commonly used?

A: They are widely deployed in industrial manufacturing, aerospace engineering, petrochemical processing, marine installations, and power generation sectors where secure, long-lasting fastening under stress or environmental exposure is crucial.Q: What is the manufacturing process for achieving high fatigue and corrosion resistance in these fasteners?

A: The fasteners are produced using precise forging, machining, and polishing techniques on high-grade nickel-chromium alloys. Additional treatments such as passivation enhance surface quality and resistance to acids, salts, and oxidation.Q: How does the non-magnetic property of Inconel Alloy Fasteners contribute to specialized usage?

A: Their non-magnetic nature ensures compatibility within sensitive environments such as electronic devices and aerospace systems, preventing electromagnetic interference while delivering high mechanical stability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Inconel 600 Products Category

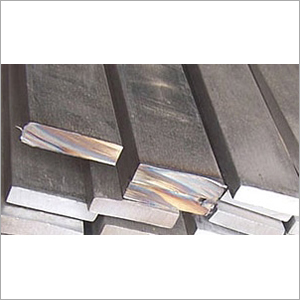

600 Inconel Flat Bars

Price 365 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Thickness : 580 Millimeter (mm)

Product Name : Stainless Steel Products

Steel Standard : AISI

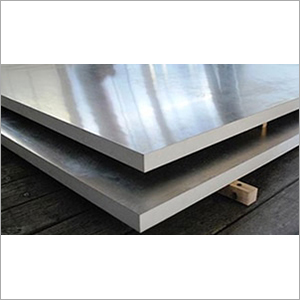

600 Inconel Plates

Price 940 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Thickness : 1120 Millimeter (mm)

Steel Standard : AISI

600 Inconel Circle

Price 355 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Thickness : 250 Millimeter (mm)

Product Name : Stainless Steel Products

Grade : 221 A

Inconel Sheets

Price 955 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Thickness : 250 Millimeter (mm)

Product Name : Steel Products

Steel Standard : AISI

Grade : 305

GST : 27AATFN5206C1ZA

Plot No. 9/51, 3Rd Kumbharwada Lane, Opposite Durgadevi Garden, Mumbai - 400004, Maharashtra, India

Phone :08045803467

|

|

NANDISHWAR STEEL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry